The influence of certain physical effects can hardly be avoided during the milling process of complex surfaces. One of those is the so called thermal squall effect of milling spindles. Due to this fact unwanted inaccuracy was a result in surface quality, which had to be fixed by follow-up processing steps. The newly developed adjustment process of exeron can avoid this inaccuracy and therefore sustainably optimise the surface quality of milled parts.

在铣削过程中,因某些复杂的物理效应是难以避免影响工件表面质量。其中之一就是过热的铣削主轴。由于在这种情况下,工件表面质量加工就不够精确,这是需要后续处理步骤。exeron新开发的ASQ功能,能持续优化铣削零件的表面质量。能够避免这种不精确性的存在。

The Advanced Surface Quality Control – ASQ – improves the surface quality and Z-precision because it takes in consideration all details of the milling process by using special control engineering. Therefore because of those control engineering interference like for example damping of minimal vibrations, the quality of milled surfaces increases in a way that follow up processing steps are reduced or not even needed anymore.

先进的表面质量控制 - ASQ - 提高了表面质量和Z轴加工精度,因为它需要考虑到铣削过程中的所有细节,通过使用特殊的控制工程,如阻尼小振动,主轴稳定的温度补偿,以致后续的表面质量处理步骤被减少或者甚至不再需要处理。

It can be managed through the permanent oscillation control of the milling head by the ASQ software. In a working process within a very small tolerance range the advantages of ASQ are therefore remarkable. The Z-precision reached with ASQ of exeron is remarkably high and always within the tolerance due to the ASQ calibrating phase. Whereas oscillations without ASQ quite often are not in the tolerance field and show obvious higher peaks.

exeron机床配置了能控制主轴振动和温度变化的ASQ功能软件。让主轴在一个非常小的公差范围之内连续高速转动。保证了Z轴加工精度非常高。,而没有配置ASQ软件控制功能的主轴偏摆和震动往往是在公差范围之外,并有时表现出明显很大的震动偏差。

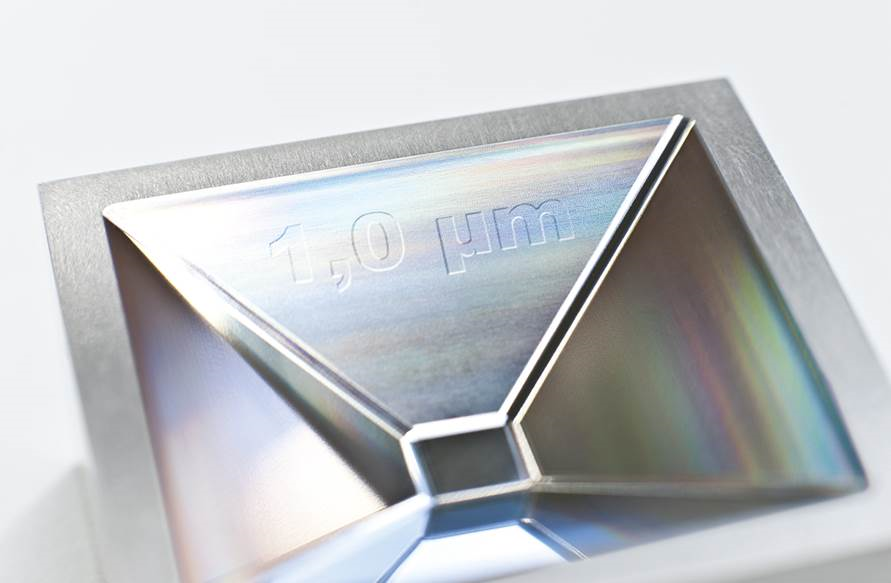

How do the parts look like with ASQ of exeron?

The surface quality of all parts increases obviously. For example a surface acerbity for brass

of Ra = 0,03 μm and for steel of Rockwell 58HRC, 0,08 μm can be reached.

To work with ASQ certain conditions are needed i.e. temperature exactness of the cooling units δ diff, max = 0.1 °C should not be exceeded. This is only possible with a torrid gas bypass. ASQ of exeron will help to get results only known before from hydrostatic drive –and bearing technology. The new adjustment process technology of exeron therefore shows impressively, what goals can be reached by excellent engineering today. ASQ by exeron stands for a first-class adjustment process at perfect cost effectiveness.

使用exeron ASQ 功能后加工的案例:

所有零件的表面质量有显著提高。

例如,黄铜粗糙度Ra = 0.03微米

钢58HRC 粗糙度R=0.08微米,

使用ASQ软件控制是 exeron机床一个巨大进步。在此之前,先进机床只是通过静压驱动和轴承技术才能达到高精度的效果,今天exeron机床通过ASQ控制功能和一流的工艺安装调整水平。同样能够做到静压驱动下精度。但我们带给客户是购买机床成本减低。性价比更高的产品。

使用ASQ功能机床硬件也是进一步提升。

如机床冷却装置的温度精确非常高,不应超过0.1°C

地址:中国(上海)自由贸易试验区美约路81号1幢3层310室

沈阳市铁西区兴华北街18号千缘财富商汇B座703室(沈阳办事处)